-

About Sleeman Mill & Lathe

Sleeman Mill and lathe Inc. caters to the plastics Industry by providing services in product design, prototyping, Mold designing, mold fabrication and machining plastics. We go through the following steps in a typical request:.

-

Why choose Sleeman Mill & Lathe?

We specialize in design, prototyping and offer one part to multi-run part production

-

Who we are

In 2007, Sleeman Mill & Lathe was born out of necessity, as the owners were dealing with numerous machine shops. Since then SML has grown into a speciality machine shop specializing in plastics, prototyping and mold-making

-

Product Design

If there is one thing that can be surely said about the future of product design is that it is changing and that too, at a rapid pace. As a business owner, if you want your product to gain instant

-

Prototyping

Invention, at its very core, is heavily dependent on flaws. Yes, you read it correctly – flaws. For inventing or creating something, it is important to have a somewhat rough idea of what the mend product will be.

-

Machining Plastics

Metal machining is a common procedure and is a more or less simple one too. It is a fact though that metal cannot be used everywhere. Say for example, in the microwave metal or steel utensils cannot be put if you want to steer clear of a disaster.

-

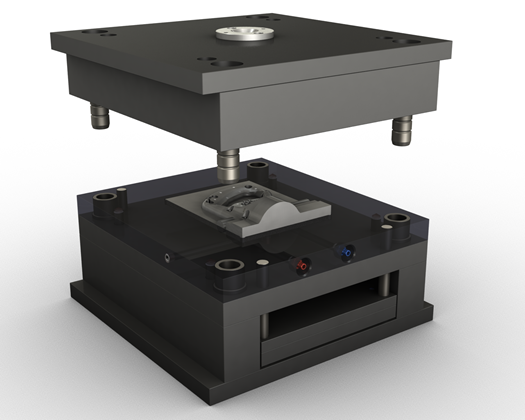

Need Help with Mold Making? Contact us !

We are experts in Mold-Making and Design