Overview of the Plastic Mold Fabrication Process

Plastic – whether one hates it or likes it; there is no denying that every single day or lives are guided by quite a few things which are made out of plastic. But did you know that most plastic objects are manufactured through a process called injection molding? Do you want a few examples? Well, washers, pulleys, valves, bottle caps, gears, keyboards, computer monitors are all made by this process. So are knobs, power tools, furniture and car panels. While these things are so varied – both in shape and in use, they are all made by the same process. Fascinating, isn’t it? This process of plastic mold fabrication is so popular because it is cost effective, especially when plastic products are being manufactured at a mass scale.

What is even more interesting is that the plastic mold fabrication process was invented more than a century ago. It was invented in the year of 1868 by John Wesley Hyatt. He had injected celluloid into a mold to create billiard balls then. Later on, he created an injecting molding machine by adding a plunger to the design. However, it was in 1946, that James Hendry took the initiative to modify Hyatt’s design of the machine by attaching a screw.

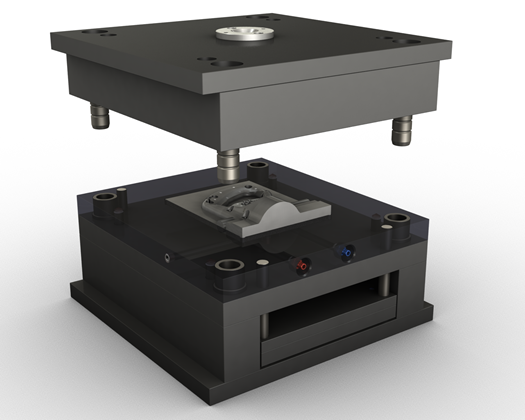

As far as plastic mold fabrication goes, the injection process has almost revolutionized the way in which things are produced in modern times. This process has made fabrication of plastic simpler and a lot faster. It will hardly be an exaggeration to state that the possibility of the use of this process is practically limitless. You might be wondering how this plastic injection molding machine actually works. To start the process, a design of the product is first developed. Then a metal mold is made and that mold is secured to the machine firmly.

The second part of this process requires that the granules or pallets of plastic material are poured into the heated barrel of the machine and it is forced into the cavity of the mold. In the third and final stage, after the cooling of the mold, the product is popped out. It sounds simple because it really is. This plastic mold fabrication process is efficient and enables the manufacturer to handle mass production of plastic products without spending a fortune on worker handlings. It saves effort, time and money and thus is enjoys uncompromised love from all manufacturers around the globe.