Why CNC Machines are Indispensable for industrial Engraving

There are various types of metal and plastic components found inside electronics which have engraving on them. These engravings are used to signify the model, type, date and manufacturer of the object. Taking into account just how miniscule these etchings are, it is quite obvious that these cannot be done by hand. Well at least you have factors like precision and time on your mind. These are achieved through the industrial engraving process and it is widely used across a variety of industries.

Mostly, CNC machines are used for these kinds of engravings. CNC stands for Computer Numerical Control and these machines operate at super high speed. These are engineered to offer precise etching on a number of surfaces including, metal, plastics, stones, ceramics, aluminium, etc. These machines can actually work on any kind of non-ferrous material.

It is quite interesting that these machines are put to work in such a way that they need very little, if any, supervision. Often the CNC machines are programmed to perform industrial engraving with no one having to oversee the process. Sometimes, only a few members of the production unit are present. These unmanned machines are so efficient that they can self change tools and even reposition the required component at predetermined intervals. Thus, manpower issues no longer pose threats of down times as these machines can keep on functioning by themselves for as long as required.

It goes without saying that industrial engraving requires precision. There is zero scope for mistakes to be committed. CNC machines are computer operated and therefore, provide a level of precision and accuracy that is impossible to be achieved by any human operated system. It is practically an error free solution and only run on programming specifications. Complex engraving tasks are accomplished easily and astounding repeatability makes things even more convenient.

With so many benefits that make the CNC machines so sought after, one would think that operating them would be extremely difficult. However, that is not the case. It is fairly easy to learn how to operate and set up CNC machines for industrial engraving. All one needs to do is enter the specification correctly on the computer. Manual changeovers which used to be so time consuming – are things of the past now.

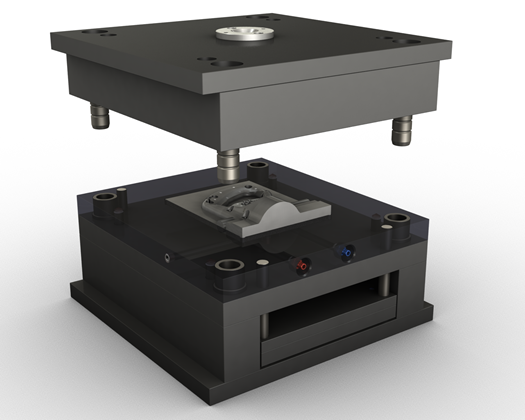

The CNC machines that are used for industrial engraving come with an automatic pallet changer. Thus multiple components can be machined simultaneously. These machines can accomplish tasks such as grinding, boring, drilling, tapping, and much more.