What is Prototyping and Why Does Your Product Need It

Invention, at its very core, is heavily dependent on flaws. Yes, you read it correctly – flaws. For inventing or creating something, it is important to have a somewhat rough idea of what the mend product will be. However, there are many a step included in between conjuring up something in one’s mind and actually being able to create it successfully. The flaws or mistakes are the very things that show the designer or the manufacturer where they are going wrong. And this process of trial and error is a necessary one before you decide to launch production. This constant testing is a defective way of figuring out whether you are taking the best route to reach where you want to go. This is what prototyping does. It helps you to realize your end goal in the best possible way.

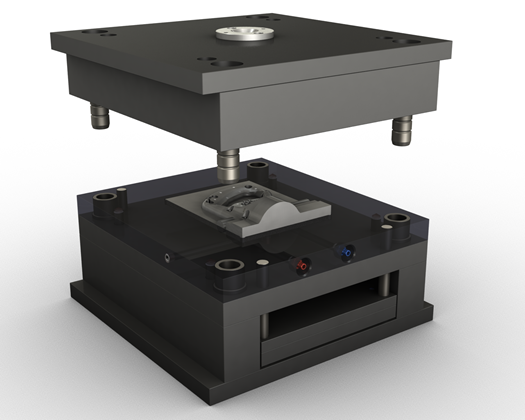

A prototype is basically the preliminary version of what you want your end product to be. It helps you to test the feasibility of your design and provides you with the chance to correct the mistakes in case there are any. From a practical standpoint, prototyping, therefore, saves the manufacturer a lot of time, effort and money which would have otherwise been wasted if a faulty design had been process with.

When a manufacturer decides to design a new product, it becomes of utmost importance to make sure that the design they are using is actually impeccable. All the components need to work seamlessly. This assurance can only be achieved through prototyping. Plastic is the most effective, affordable and therefore most widely used material needed for the said process. Besides, it also works for achieving the best level of accuracy.

In prototyping, attaining precision is vital. Irrespective of which industry you function in, you would not want to come across an unprecedented problem in the design halfway through the production process. However, the engineering and manufacturing industries are more particular about getting such problems solved at the earliest, in order to avoid massive losses o property, assets or worse, lives.

Plastic prototyping necessitates an in depth and extensive knowledge of 2D and 3D CAR modelling as well as the translation of those designs onto CNC machinery. It is this machinery that helps to give accuracy to your product’s prototype. Plastic prototyping offers designers to make proper use of a variety of techniques with the help of deposition modelling, laminated object manufacturing, laser sintering, 3D printing, stereo lithography and much more. These processes enable faster production of prototypes no matter how complex the design might be.