How Plastic Part Production Is Benefitted by the Injection Molding Process

The injection molding method for producing plastic objects has been used by industries for over a century now. It was first used by one John Wesley Hyatt in 1868. He injected celluloid into a mold and voila! Brand new billiard balls were created. It was Hyatt who invented the very first plastic molding machine. Hyatt’s design was further modified by James Hendry and the rest, as they say, is history. There can be no denial to the fact that even though plastic injection molding is a fast and beneficial method of part production, it is also a rather versatile one. Then why is it preferred by so many industries around the world? The answer to that would be because this method has quite a few advantages over other processes of plastic molding. It is a simpler and faster process along with being highly efficient.

In case you are wondering why injection molding is deemed as the best process for plastic part production, take a look at the list o benefits it comes with:

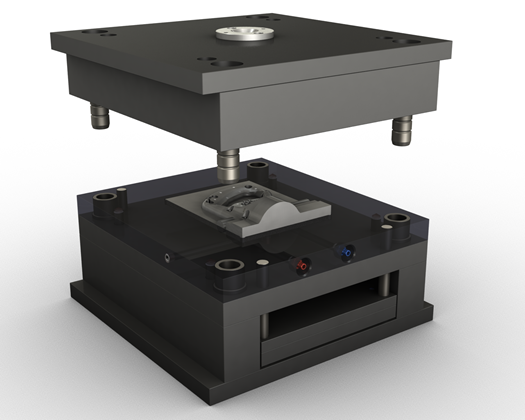

- Attaining detailed features complex contours and difficult geometry is no problem for injection molding. As the injection molds are subjected to extremely high pressure, incorporating detailed designs with minute contours become easier. It is this high pressure that allows intricate shapes of the design to be rendered flawlessly in the design.

- This process of plastic part production is highly efficient. After the mold has been created according to the client’s specifications, the actual molding and extraction of parts go very smoothly and is completed in a short amount of time. Thus, it saves the manufacturer a lot of time, effort and money.

- Part production through injection molding allows the use of filters in the molds. These fillers reduce the density of the plastic at first and then allow the parts to be strengthened after the molding process has been completed. Thus the parts have greater durability than the parts produced through other processes.

- Moreover, this method enables the use of various kinds of plastic as is required for specific types of part production. The best part is different types of plastic can be used simultaneously through co-injection molding.

- As this process of plastic part production is mostly, if not entirely, conducted through machines, precision takes the front seat. Hardly any work is required after the molding process is completed when the parts are extracted from the molds. Plus this is an environment friendly process.