A Closer Look at the Process of Machining Plastics

Metal machining is a common procedure and is a more or less simple one too. It is a fact though that metal cannot be used everywhere. Say for example, in the microwave metal or steel utensils cannot be put if you want to steer clear of a disaster. On the other hand plastic utensils can be easily used in microwaves and that too, repeatedly. Plastic, with its many properties and uses, is considered reliable for many purposes. Another important fact that should not be overlooked is that plastic is way cheaper than metals. It is precisely for the aforementioned reasons that plastic is so in demand. Of course, plastic has to be machined too and machining plastics is not nearly as simple as machining metals.

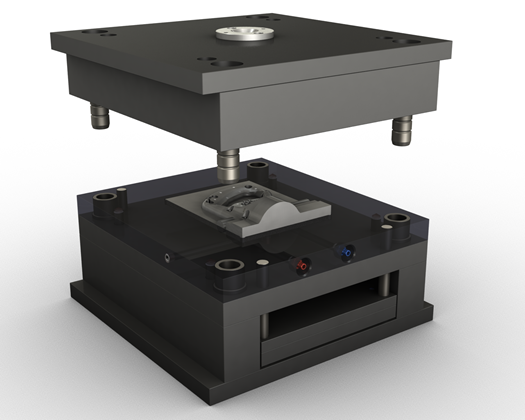

Machining plastics require an augmented set of skills. It is significantly different than the process of plastic melding and is done in much higher quantities than the molding too. Machining of plastics is needed for some very specific industries and the need for precession is much higher. Plastic is a malleable and soft substance, dealing with which requires ultimate care. Engineers are often faced with various challenges when they are dealing with the process of machining this substance. One of the most common impediments faced by the engineers is the unusual shape of the object in which the plastic has to be molded in. Such problems can be solved only by using the right type of materials that have proper tolerances.

Machining plastics is required for avant garde industries such as aerospace, hydraulics, pharmaceuticals, culinary and electronics. In these industries machining is given more importance than the process of molding. This is because in molding it is almost impossible to achieve the precision of minute parts which are used in the aforementioned industries.

Machining plastics nowadays is heavily dependent on the method called CNC. CNC refers to computer numerical control and enables tight tolerances to be followed during machining. This type of machining provides improved texture, optical clarity, etc. It is mostly used for obtaining medium as well as high capacity parts. This process also allows costs per part to remain extremely low when mass production is underway.

CNC method of machining plastics is mainly achieved for attaining highly complex contours, angles, threading and corrugations. The computerized platform permits repeatability and that too, quite easily. The digital platform allows the entire process to be closely monitored and the final product to be flawless.